From concept to design to completed system or lean manufacturing cells, MCI/Screwdriver Systems will provide you with automatic fastener handling equipment of the highest quality within your required timeframe and well within your budgetary guidelines. With our design capabilities, manufacturing expertise, and stringent quality control standards you can rest assured that there is no need to look elsewhere for bits and pieces of a system.

MCI/Screwdriver Systems’ years of successful parts handling experience are incorporated into the collateral design features of our automatic screwdriver receiving heads and polycast part handling and feeding systems. All tooling that comes in contact with your parts is made of durable 300 series stainless steel or polymer materials to prolong equipment life and lower contamination possibilities. A Lexan hinged lid also prevents parts of equipment from exterior contamination. Durable stainless, or tool steel tracks are custom designed to orient your parts in a way that always fits your application and space requirements. For ease of maintenance and reliability, our polycast vibratory parts handling systems feature interchangeable precision machined tooling. Put the experience of MCI/Screwdriver Systems to work for you today.

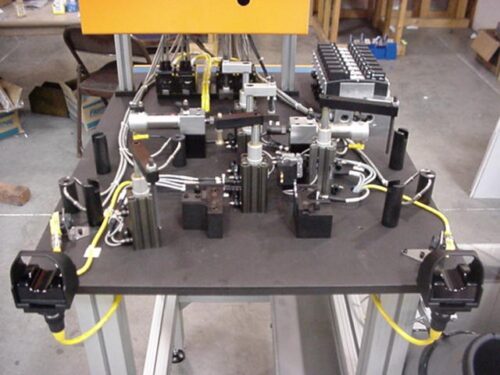

Lean Systems

In addition to automatic screwdrivers, we developed our custom lean cell systems specifically to overcome the inherent difficulties in handling, feeder, and orienting parts that can be handled at a work station rather than fully automating it online. Our systems are capable of providing a constant flow of work output.

MCI/Screwdriver also provides single station assembly mechanisms complete with pneumatic and electric automatic screwdrivers that assemble fasteners tracked from custom vibratory stainless steel parts feeders, our patented Polycast feeder family, or our custom or standard step feed family.

With our unique and custom design capabilities, manufacturing expertise, and stringent quality control standards, you can rest assured that there is no need to look elsewhere for bits and pieces of a system. From concept to completed system, MCI will provide you with a system of the highest quality within your required timeframe and budgetary guidelines.