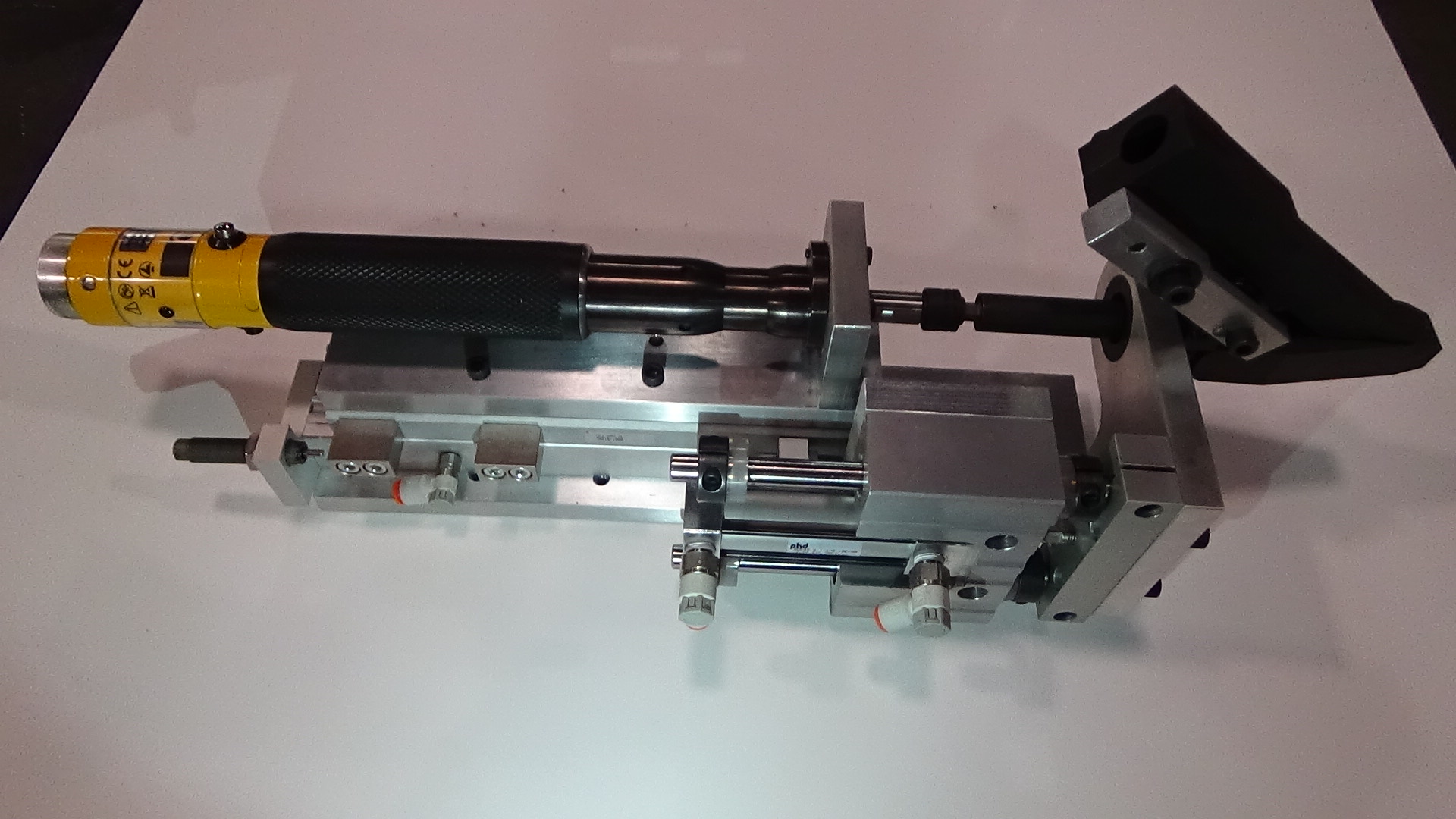

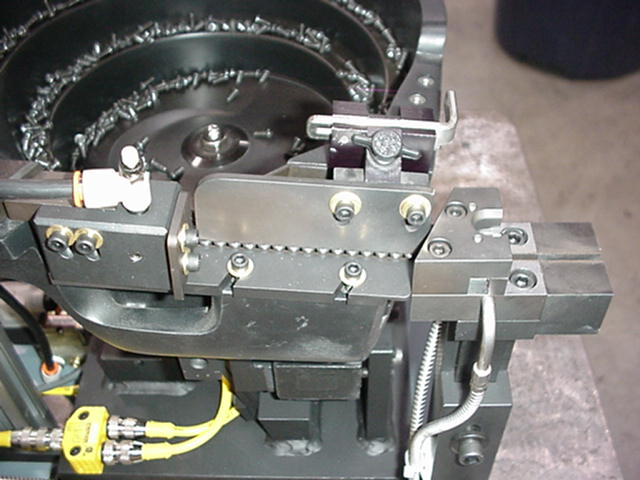

Systems

MCI Screwdriver is committed to providing continuous efforts to achieve stable and predictable process results.

Our Process

- 1CUSTOMER RELATIONSHIP

- Establish line of communication

- Establish MCI values/loyalty

- 2PROJECT EVALUATION

- Obtain required information to determine best options for application

- Extend proposal for project

- 3SYSTEM DEVELOPMENT

- Present system approval files for approval to begin fabrication

- Manufacture system(s) to approved specifications

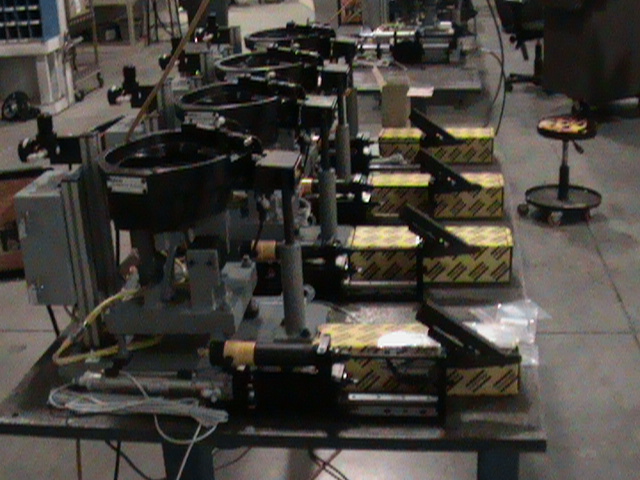

- 4SYSTEM VERIFICATION

- On time completion

- Test system in-house for verification

- In-house or video run-off of equipment

- Provide system documentation in a timely manner

- 5SUPPORT

- Provide in-house and on-site support

- Continue to establish process improvements and customer relations